Metallographic Image Analysis

Best Price:

Buy Metallographic Image Analysis for $7,500.00 at @ Megadepot.com

No coupon is required — this is the standard retail price.

Set a price drop alert to never miss an offer.

Price Comparison

| Seller | Contact Seller | List Price | On Sale | Shipping | Best Promo | Final Price | Volume Discount | Financing | Availability | Seller's Page |

|---|---|---|---|---|---|---|---|---|---|---|

|

BEST PRICE 1 Product Purchase

|

|

$7,923.00 | $7,500.00 |

|

$7,500.00 | See Site | Visit Store |

Product Details

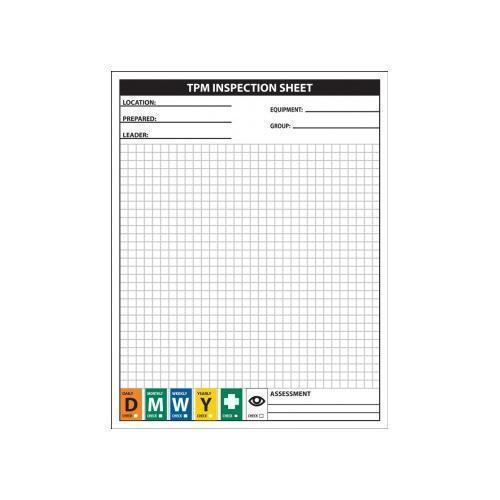

Metallographic Image Analysis Modules:Basic Meaurement - Manually draw lines on traces, shapesGrain Size - Heyn lineal intercept procedure, Abrams Three-Circle Procedure, Random Line Intersection Methods, Jeffries Planimetric Method, Comparison Procedure MethodGray Iron - Graphite flakes are described by the type and distribution of graphite in cast iron with the following three classifications: Type VII for graphite form, A-E distribution of graphite and graphite size (1-largest to 8-smallestSpheroidal or Ductile Gray Iron - Nodularity describes the type and distribution of graphite in cast iron with the following three classifications: Types I-VI for graphite form, A-E distribution of graphite and graphite size (1-largest to 8-smallestCarbide - Estimates the amount of iron carbide or cementation in steels and cast irons. Carbide is measured as a volume fractionPorosity - Porosity Porosity are voids in the material caused by entrapped air and incomplete or poor sintering. Porosity can be measured as a volume fractionInclusion Rating - Characterizes the type, size and severity of the inclusion in wrought steel. The types include: SULFIDE (A TYPE), ALUMINA (B TYPE) SILICATE (C TYPE), GLOBULAR (D TYPE). Size is characterized as H-heavy or T-thin. Severity Level is based on the number or length Coating Thickness - Measures a coating thickness after cross sectioning the specimen Spheroidization - Nodules acquire blue color and non-nodules are set to a red color. Nodules are designated by Roman numbers from I to VI and by size using Arabic numbers 1 to 8. The results are reported along with the calculated nodules/ sq mmDecarburization - Decarburization is the loss of carbon at the metal surface due to chemical reaction(s) with the contacting media. The analysis estimates the average or greatest depth of decarburization in hardened or non-hardened steel productsSegmentation - Phases are defined as physically homogenous and distinct constituents of the material. The phases are partitioned or segmented based on the intensity / gray scale of the various constituents and are characterized and measured using area or volume fraction measurementsThis range of Image analysis systems provide a single fully integrated analytical tool for study and documentation of microstructures using fast and automatic image processing techniques. Quantification of phases ( ASTM E566, ASTM 1245 ), inclusions ( ASTM E454 / E1245 ), Grain Size ( ASTM E112 ), Nodularity (ASTM A247), Porosity (ASTM A276), Decarburization (ASTM E1077), and coating thickness (ASTM B487) is achieved by capturing the picture through a high resolution color digital camera interfaced to the camera port of the metallurgical microscope. The image is imported onto a Pentium based PC by a specially designed image acquisition card for preview and storage.

Copied

Copied