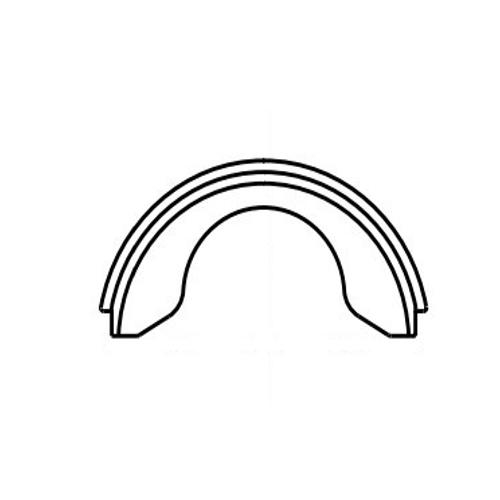

Forged Aluminum Grooved Clamp

Best Price:

Buy Forged Aluminum Grooved Clamp for $40.11 at @ Megadepot.com

No coupon is required — this is the standard retail price.

Set a price drop alert to never miss an offer.

Price Comparison

| Seller | Contact Seller | List Price | On Sale | Shipping | Best Promo | Final Price | Volume Discount | Financing | Availability | Seller's Page |

|---|---|---|---|---|---|---|---|---|---|---|

|

BEST PRICE 1 Product Purchase

|

|

$40.58 | $40.11 |

|

$40.11 | See Site | Visit Store |

Product Details

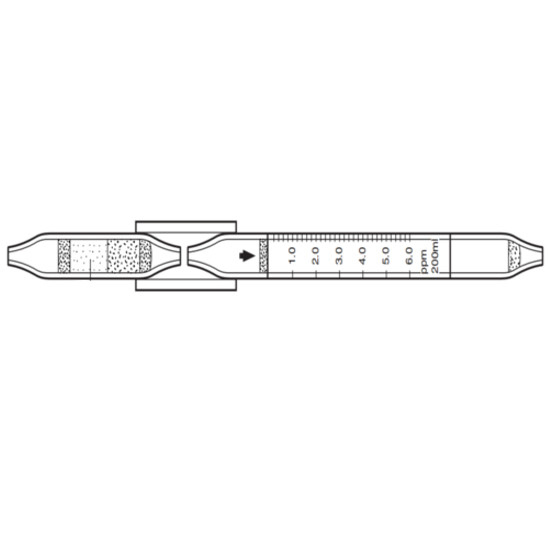

ApplicationsGrooved clamps are often used on pipe connections on dry bulk tankers in place of welding offering the ability to adjust, change or replace pipe sections without the need for a permanent joint such as a weld.UseDesigned to join two pieces of pipe together.White Buna-N seal is for use in dry bulk food applicationsUse of lock nuts prevents clamps from loosening in high vibration applicationsSpecificationsManufactured to fit new and existing grooved pipe connections.Weight: 1.38 lbs.FeaturesPrecision forged to provide an exact fit and great appearanceUnlike steel groove clamps that secure pipe ends with high clamping force against tubing/piping walls, the Dixon aluminum clamp takes the full bolt force and locks into the groove of the tube/pipe, preventing distortion of the tube/pipe diameter.Precision casting and machined dimensions provide an exact fit and great appearanceEasy to preform maintenanceLeak-tight connectionConstructionAluminum bodySteel bolts/nutsWhite Buna-N sealsHow it worksThe two pipes are butted to one another each pipe has a groove that runs the circumference of the pipe exterior. The grooved clamp has ridges that lock into the two pipe grooves and a gasket is compressed to the pipes to create a leak-tight seal.NoteSupplied clamp gasket must be installed prior to use. Ships separately. Replacement gaskets are available.Safety notesTorque the bolts until metal to metal contact occurs at the bolt pads (about 20 ft-lbs). Bolts must be tightened evenly to prevent gasket pinching and clamp breaking. DO NOT tighten one side then the other. Over-torquing will not improve sealing and may result in failure of the clamps. DO NOT torque bolts over 30 ft-lbs.

Copied

Copied